Dairy & Food

Yili

Case Study • August 15, 2024

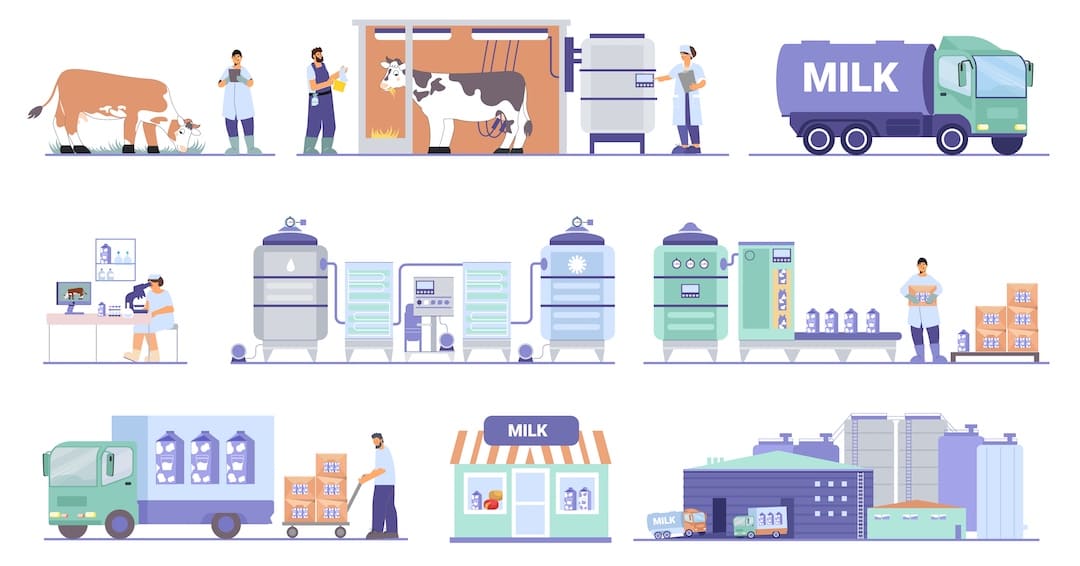

How Yili Transformed Its Supply Chain Operations with Convect AI's Supply Chain Planning Solution

August 15, 2024

Dairy & Food

8 min read

This case study details how Yili, Asia's largest dairy producer, revolutionized its supply chain by adopting Convect AI's Supply Chain Planning solution. By transitioning from Excel-based planning to AI-driven optimization, Yili achieved a 17% reduction in transportation costs and increased productivity by 5%.